In heavy equipment manufacturing, precision is not simply a technical requirement—it is the foundation of reliability. From power transmission efficiency to long-term operational stability, the quality of critical components directly affects machine performance. Among these components, spiral bevel gears play a vital role in ensuring smooth power transfer and accurate direction changes within complex drive systems.

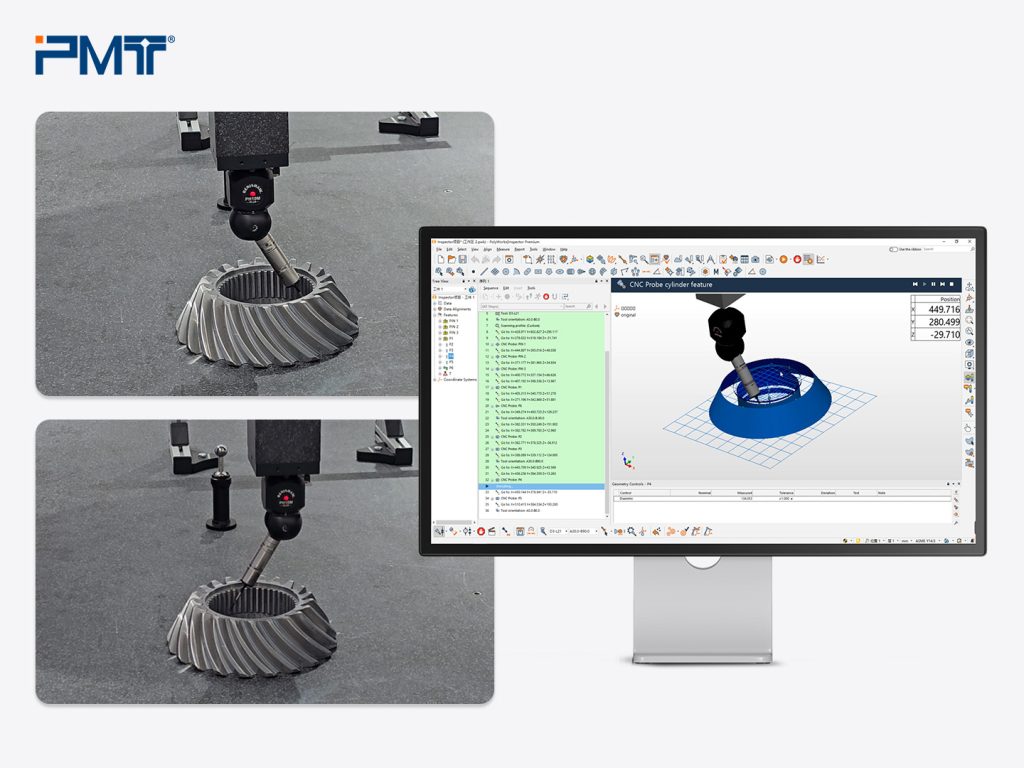

To meet increasingly strict quality standards, manufacturers are turning to advanced coordinate measuring machine (CMM) solutions that deliver both accuracy and efficiency. This case highlights how a PMT FUTURE Bridge CMM, combined with professional measurement software, supports high-precision spiral bevel gear inspection in a demanding industrial environment.

Project Background

The customer is a foreign-invested enterprise with long-term expertise in heavy equipment manufacturing. Its business covers the research, design, production, sales, and technical services of core industrial equipment, including tube rolling mills and related transmission systems.

Within these systems, spiral bevel gears are key functional components. They are responsible for precise torque transmission and 90-degree directional changes under heavy loads. Due to their critical role, the customer maintains a strict internal quality control system, particularly for gear geometry and form-and-position tolerances.

To further strengthen inspection capability and ensure stable gear performance during assembly and operation, the customer partnered with PMT to implement a high-precision CMM-based measurement solution.

Clear Measurement Objectives Before Inspection

Before formal inspection, PMT engineers carefully reviewed the customer’s technical drawings to confirm all required measurement features. Based on the functional requirements of the spiral bevel gear, the inspection objectives were clearly defined in advance to ensure that all measured results directly support assembly and operational performance.

The key measurement objectives included:

- Perpendicularity

Inspected to avoid assembly tilt between mating components. Accurate perpendicularity helps ensure proper alignment and reduces uneven load during operation. - Parallelism

Controlled to prevent vibration and performance degradation. Poor parallelism can negatively affect machining accuracy and long-term transmission stability. - Coaxiality

A critical parameter for spiral bevel gears. Accurate coaxiality ensures stable meshing and reliable power transmission. In this application, coaxiality accuracy reached up to 1 μm. - Total Runout

Measured to detect potential part defects and form deviations. Controlling total runout helps ensure smooth rotation and stable operation of the transmission system.

By clearly defining these objectives at the beginning, PMT ensured a focused, efficient, and application-oriented inspection process.

PMT CMM Solution for Spiral Bevel Gears

To address these inspection challenges, the customer adopted a PMT FUTURE Bridge coordinate measuring machine integrated with professional measurement software.

The bridge-type CMM structure provides excellent rigidity and stability, making it well suited for high-precision industrial measurement tasks. Combined with advanced probing and software analysis capabilities, the system enables comprehensive evaluation of complex gear geometry in a single setup.

Outstanding Accuracy Performance

One of the key reasons the customer selected PMT was its proven accuracy performance.

Using the PMT FUTURE Bridge CMM, the system achieves coaxiality measurement accuracy down to 1 μm, allowing even the smallest deviations to be reliably detected. This level of precision ensures that spiral bevel gears meet strict assembly and meshing requirements, supporting stable transmission performance in heavy-duty applications.

High repeatability further guarantees consistent inspection results across multiple parts, reinforcing confidence in quality decisions.

Efficient and Comprehensive Inspection

Beyond accuracy, inspection efficiency was another important consideration.

With PMT’s CMM solution, multiple form and position tolerances—including perpendicularity, parallelism, coaxiality, and total runout—can be inspected within a single measurement program. This approach significantly reduces inspection time compared with traditional measuring tools, which often cannot evaluate these parameters effectively or consistently.

The result is a streamlined inspection process that improves productivity while maintaining high measurement reliability.

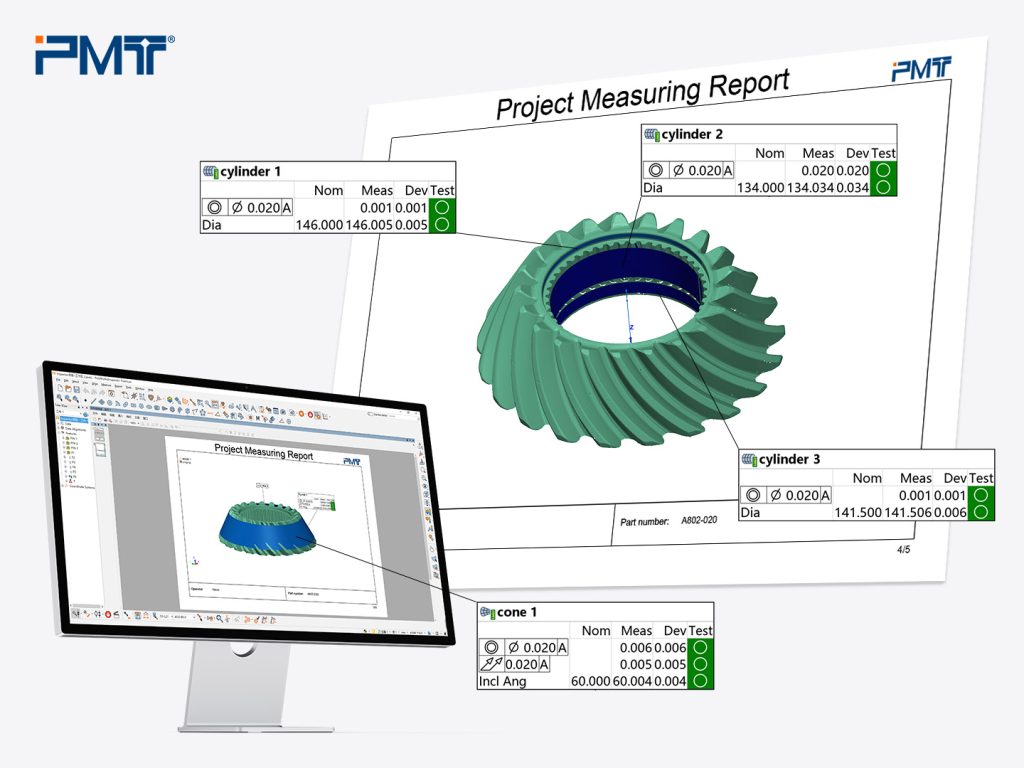

Fast Analysis and Data-Driven Quality Control

The integration of measurement software further enhances inspection efficiency and usability.

Measurement results are automatically transformed into clear, visualized inspection reports, allowing engineers to quickly understand part quality status. In addition, the system supports SPC (Statistical Process Control), enabling long-term trend analysis and process optimization.

This data-driven approach helps the customer move beyond pass/fail judgments and toward continuous quality improvement.

Applications Across Multiple Industries

Spiral bevel gears are widely used across industrial sectors due to their high efficiency, load capacity, low noise, and compact 90-degree transmission design. Typical application areas include:

- Automotive manufacturing

- Machine tools

- Heavy machinery

- Shipbuilding

- Wind energy systems

- Aerospace and defense

The PMT CMM solution demonstrated in this project is well suited for these industries, where both precision and reliability are essential.

Conclusion

This project demonstrates how PMT’s FUTURE Bridge CMM, combined with advanced measurement software, delivers a reliable and high-precision solution for spiral bevel gear inspection. With coaxiality accuracy reaching 1 μm, efficient multi-tolerance inspection, and powerful data analysis capabilities, the solution fully supports the stringent quality requirements of heavy equipment manufacturing.

By enabling accurate, repeatable, and efficient measurement, PMT helps manufacturers ensure stable gear performance and long-term equipment reliability.

About PMT

PMT is a professional coordinate measuring machine supplier dedicated to providing high-precision metrology solutions for industrial manufacturing. With a strong focus on accuracy, efficiency, and practical application, PMT supports customers worldwide in achieving reliable quality control and smarter production processes.

If you are looking to enhance gear inspection or optimize critical component measurement, PMT is ready to support your next step in precision manufacturing.