As production environments become more complex, manufacturers need inspection solutions that can move with the process. This is where portable measurement shows its real value. For PMT, portability is not just a feature—it is a practical response to real shop floor challenges.

This article focuses on how PMT portable measuring arms, as a type of portable CMM, bring precise measurement directly to the production site. Through proven industrial applications, we show how portable CMM solutions help manufacturers improve efficiency, control quality, and respond faster to production changes.

From the Lab to the Shop Floor: Why Portability Matters

Traditionally, precision measurement has been carried out in dedicated metrology rooms using fixed Coordinate Measuring Machines. However, large parts, heavy components, and complex structures often make transportation difficult, time-consuming, or impractical.

Against this background, portable CMM technology has become an effective alternative. By bringing the portable measuring arm to the workpiece instead of moving the workpiece to the measuring system, manufacturers can reduce handling time, avoid repositioning errors, and obtain inspection results earlier in the process.

As a result, PMT portable measuring arms enable measurement to move closer to production, supporting faster feedback and more efficient quality control.

Core Strengths of PMT Portable Measuring Arms

Before reviewing specific applications, it is important to understand why PMT portable CMM solutions perform well in on-site measurement tasks.

First, flexible installation allows the portable measuring arm to be mounted directly on the workpiece, a tripod, or nearby structures without special foundations. Second, stable measurement accuracy supports dimensional and geometric tolerance inspection under real workshop conditions. Third, PMT INSPECT measurement software integrates measurement, evaluation, batch inspection, and reporting into one streamlined workflow.

Together, these capabilities make PMT portable measuring arms a complete on-site measurement solution rather than just a mobile inspection tool.

Application 1: Machine Tool Industry – Grinding Spindle Inspection

In the machine tool industry, grinding spindles are typically heavy and produced in large batches. Common inspection tasks include coaxiality of inner bores, perpendicularity between bore axes and flange faces, and parallelism relative to mounting surfaces.

In this scenario, PMT portable measuring arms demonstrate clear advantages. During deep bore inspection, the portable CMM supports stable contact measurement. For larger or deeper holes, extended probe options allow the measuring arm to reach the bottom of the bore without complex setup.

In addition, the portable measuring arm can be mounted directly on the spindle using magnetic bases, eliminating the need for additional fixtures. With batch inspection functions in PMT INSPECT software, all parts are measured using the same program, ensuring consistent evaluation standards and reducing operator influence.

Application 2: Aerospace Manufacturing – Wing Fixture Inspection

Aerospace fixtures are designed to support large wing structures while preventing surface damage. The key inspection requirement is verifying the accuracy of complex contact surfaces.

Here, portability becomes a decisive advantage. PMT portable measuring arms adapt easily to large fixtures on site. Using point-based alignment methods, the portable CMM can align the physical fixture with the CAD model even when clear geometric features are limited.

After initial alignment, additional surface points are collected to improve matching accuracy. The software’s best-fit function automatically calculates optimal alignment results, providing reliable surface deviation data. Automatic point collection further ensures uniform point distribution and repeatable inspection results.

Application 3: Construction Machinery – Welded Fixture Inspection

Construction machinery components are often large, welded, and geometrically complex. Many weld areas are difficult to access, making traditional inspection methods inefficient.

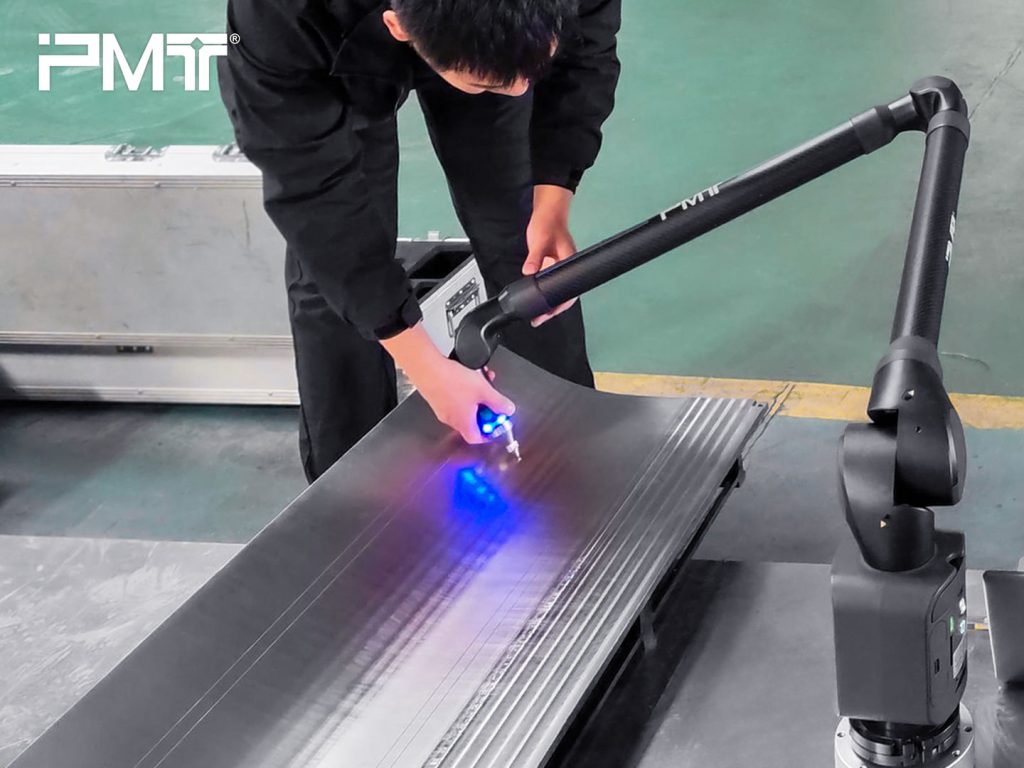

In this case, PMT portable measuring arms provide a flexible inspection solution. Their lightweight carbon fiber structure allows operators to reach inside cavities, around weld seams, and into narrow spaces. The portable CMM can be easily moved between workstations, supporting continuous inspection across the shop floor.

By accurately measuring hole sizes, hole distances, profiles, and weld positions, manufacturers can verify tolerances against drawings efficiently and reliably.

Application 4: Large Structural Parts – Extended Measurement Range

For large components such as excavator booms, key inspection tasks focus on the geometric accuracy of transmission joints, including coaxiality, parallelism, and spatial distances between bearings.

PMT portable measuring arms handle these requirements with flexible articulation, allowing accurate point collection inside bearing bores. To cover extra-large measurement spans, standard reference spheres can be used for coordinate bridging, effectively extending the measurement range of a single portable CMM.

This approach allows manufacturers to complete large-scale measurements without changing equipment.

Application 5: Automotive Industry – Vertical Checking Fixtures

In automotive inspection, fixed CMMs are commonly used. However, when checking fixtures must remain in a vertical position, Z-axis travel limits can restrict measurement.

In such cases, PMT portable measuring arms serve as an ideal complement. Mounted on a mobile tripod, the portable CMM can reach elevated features without moving the fixture. Flexible alignment methods support different datum systems, while real-time measurement enables “adjust and measure” operations during fixture setup.

Once adjustment is complete, final inspection data can be generated immediately, improving setup efficiency and ensuring delivery quality.

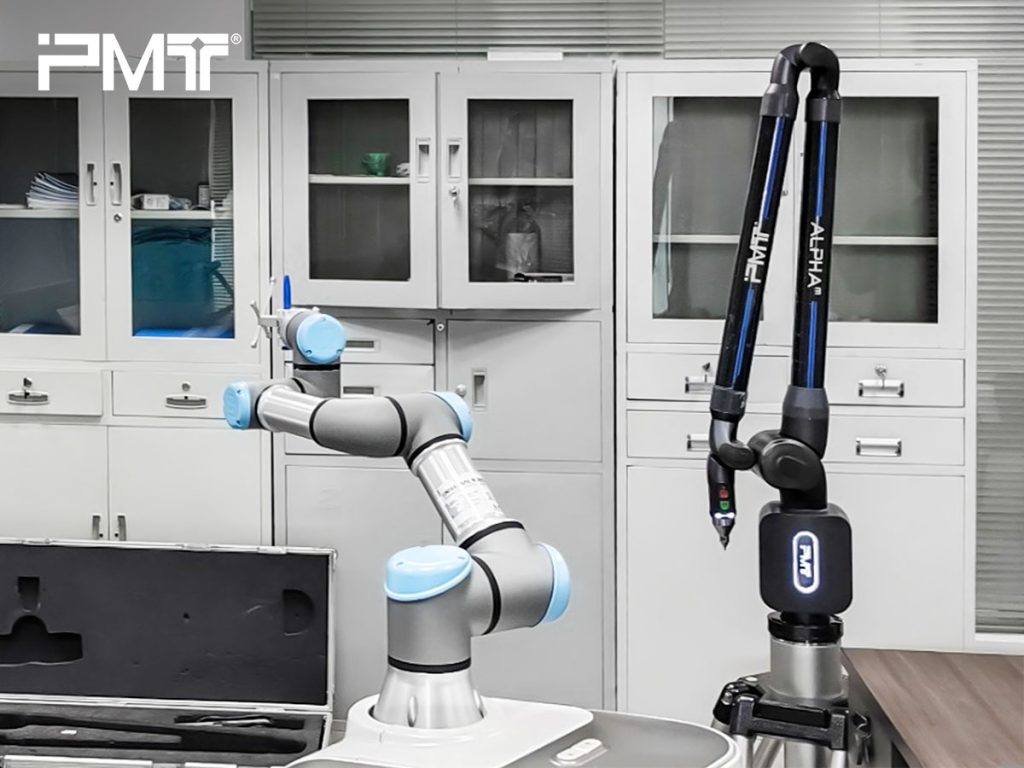

Application 6: Medical Manufacturing – Robot and Device Inspection

Medical device manufacturing is characterized by small batch sizes, frequent design changes, and strict quality requirements. PMT portable measuring arms are well suited to this environment.

Thanks to their mobility, portable CMM systems support in-place inspection and in-machine measurement, reducing errors caused by repeated handling. For delicate components, non-contact measurement options help protect sensitive surfaces.

From a cost perspective, portable measuring arms do not require a dedicated metrology room. One system can support multiple production lines, making it a practical and economical solution for medical manufacturers.

Conclusion: Turning Portability into Long-Term Measurement Value

By focusing on portability, PMT portable measuring arms change how measurement is applied in manufacturing. Measurement moves from the laboratory to the shop floor, from delayed feedback to real-time response, and from a cost-driven task to a value-creating process.

Across industries—from machine tools and aerospace to automotive, construction machinery, and medical manufacturing—PMT portable CMM solutions help manufacturers solve real measurement challenges with practical and reliable technology.

Learn how PMT portable measuring arm solutions can bring precision directly to your production site. Contact PMT to find the right portable CMM for your application.