On July 19, 2025, China announced the commencement of the hydropower project in the lower reaches of the Yarlung Zangbo River in Nyingchi, a city in China’s Xizang autonomous region. As a key initiative under the country’s 14th Five-Year Plan, this project is of great importance in advancing China’s energy strategy, promoting economic development in border areas, and strengthening its international influence, while setting new global standards for hydropower development.

By utilizing the vast energy potential of the Yarlung Zangbo River, this groundbreaking project will also drive the growth of engineering machinery commonly employed in sectors like hydraulics, mining, railways, and highways in the nearby areas. These industries demand high performance under extreme working conditions, with a strong emphasis on manufacturing precision and quality stability.

As one of the core quality control methods in engineering machinery, PMT portable CMM (measuring arm) offers the advantage of measuring anytime and anywhere, providing innovative technical value throughout the R&D, production, and evaluation processes.

Applications in Engineering Machinery

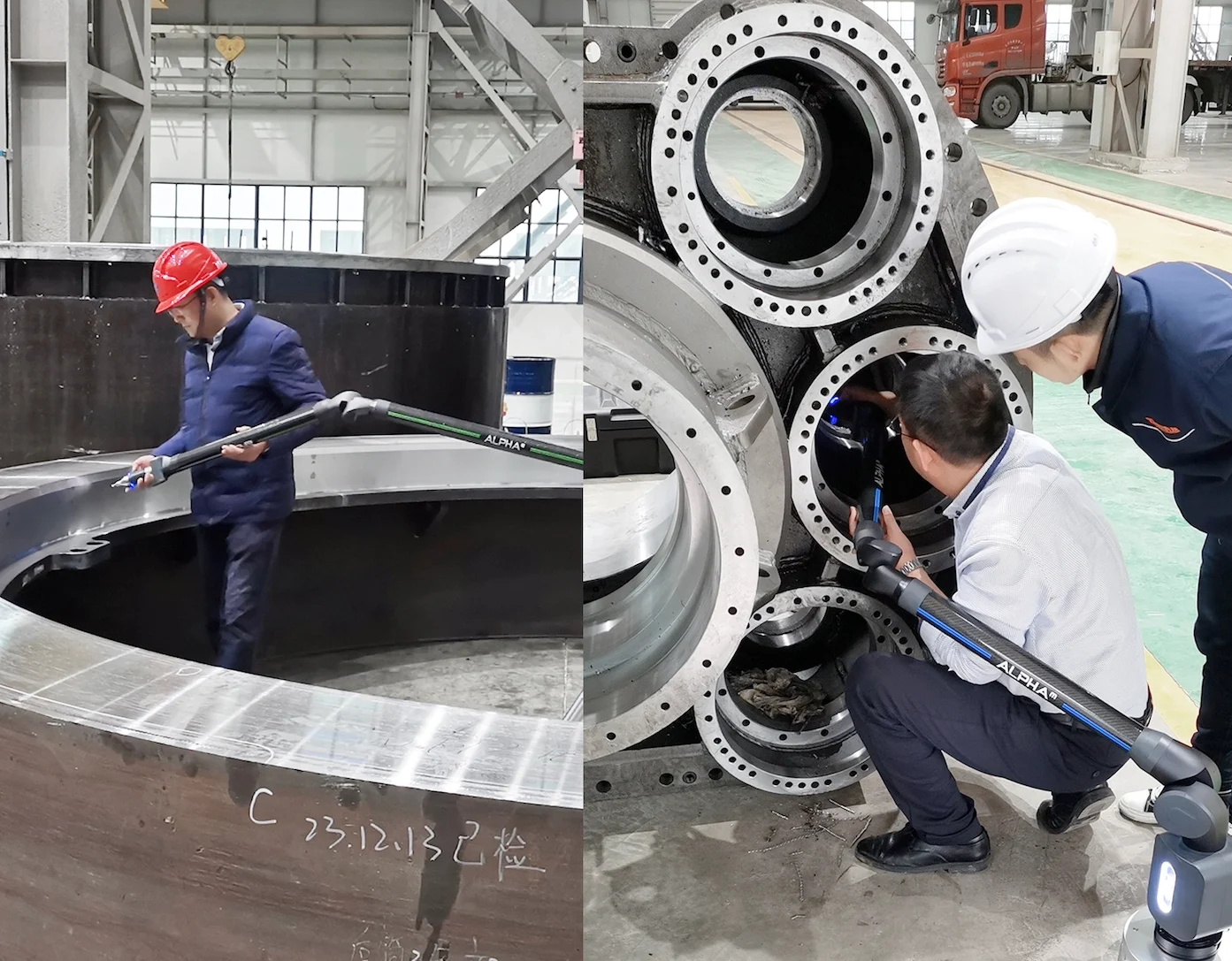

1.? Measurement of Shield Machine (Small Machine & Main Shaft)

A shield machine plays a crucial role in tunnel excavation within engineering machinery. Currently, the front shield relies primarily on manual measurements, often resulting in significant errors due to inconsistent measuring positions and variations in worker skills and proficiency. Additionally, the confined space and complex working environment within the shield machine pose serious safety risks to personnel.

With its high portability and precision, the PMT measuring arm has found extensive application in this field, significantly reducing safety risks and enhancing the efficiency and automation of tunnel construction.

2.? Measurement of Casting Mold for Engine Cylinder Block

The casting mold of the engine cylinder block is designed to precisely shape steel into complex components. Its high precision is essential for enhancing engine performance and ensuring a reliable power supply.?

However, thermal deformation and wear during die casting can lead to dimensional inaccuracies, making regular size inspections crucial. The PMT portable measuring arm overcomes environmental challenges and removes the need for pre-set reference standards typically used in traditional methods. The PMT Arm’s highly adaptable measurement capabilities contribute to improving mold design.

3.? Measurement of Excavator Component

As the demand for diverse engineering tasks increases, modern excavators are designed to switch between multiple working attachments. They are indispensable in earth-moving operations during the early stages of hydraulic projects.

The PMT measuring arm delivers accurate measurements of critical dimensions on key excavator components. By probing critical areas and constructing geometric features such as planes, cylinders, and circles, the measuring arm can swiftly verify the width of installation grooves, parallelism, symmetry, and concentricity of mounting holes. This helps avoid installation problems and improper fittings caused by machining errors during production, ultimately ensuring the optimal performance of the equipment.

Quick adjustments can be made in real-time based on the probe’s coordinate values using the PMT Arm, thereby improving the accuracy and efficiency of component production and assembly.

4.? Measurement of Engineering Vehicle Chassis

The engineering vehicle chassis is essential for supporting loads in hydraulic projects, preventing deformation or fractures under heavy loads.

Typically welded from large steel or iron castings, chassis precision is impacted by self-weight and thermal deformation during welding, leading to potential post-cooling deformations.

Therefore, it’s crucial to use PMT portable measuring arm with software for routine inspections. The equipment evaluates GD&T features, such as concentricity and flatness of mounting holes, to ensure precise assembly and prevent defects that may lead to batch scrapping. This ultimately enhances the safety and reliability of engineering vehicles in the challenging working conditions of hydraulic projects.

5.? Measurement of Ore Crusher Station Frame

The ore crusher station frame provides support for crushing equipment, stabilizing its weight and withstanding impact forces during the processing of ores, rocks, and other materials.

Due to the large size of the frame, traditional measurement methods become difficult to apply, with some dimensions even being undetectable. The PMT measuring arm effectively verifies the consistency of drawings and samples, easily checking space dimensions and geometric tolerances. Additionally, the 7-axis measuring arm and SD laser line probe enable reverse verification of samples.

The PMT Arm’s features include the following aspects:

- Quick Installation: The PMT measuring arm can be easily and rapidly installed on-site.

- Quick Acquisition: Only four points are needed to measure planes, calculate flatness, and analyze deformation.

- Quick Measurement: Concentricity is measured without additional tools; simply measure the cylindrical feature and use the software’s axis construction function for quick

- Quick Verification: For reverse verification of complex surfaces on the crusher station, rapid scanning with portable CMM’s extended measurement range ensures accurate

Other Applications

The hydraulic project will also be applied in railway track laying and valve body manufacturing.

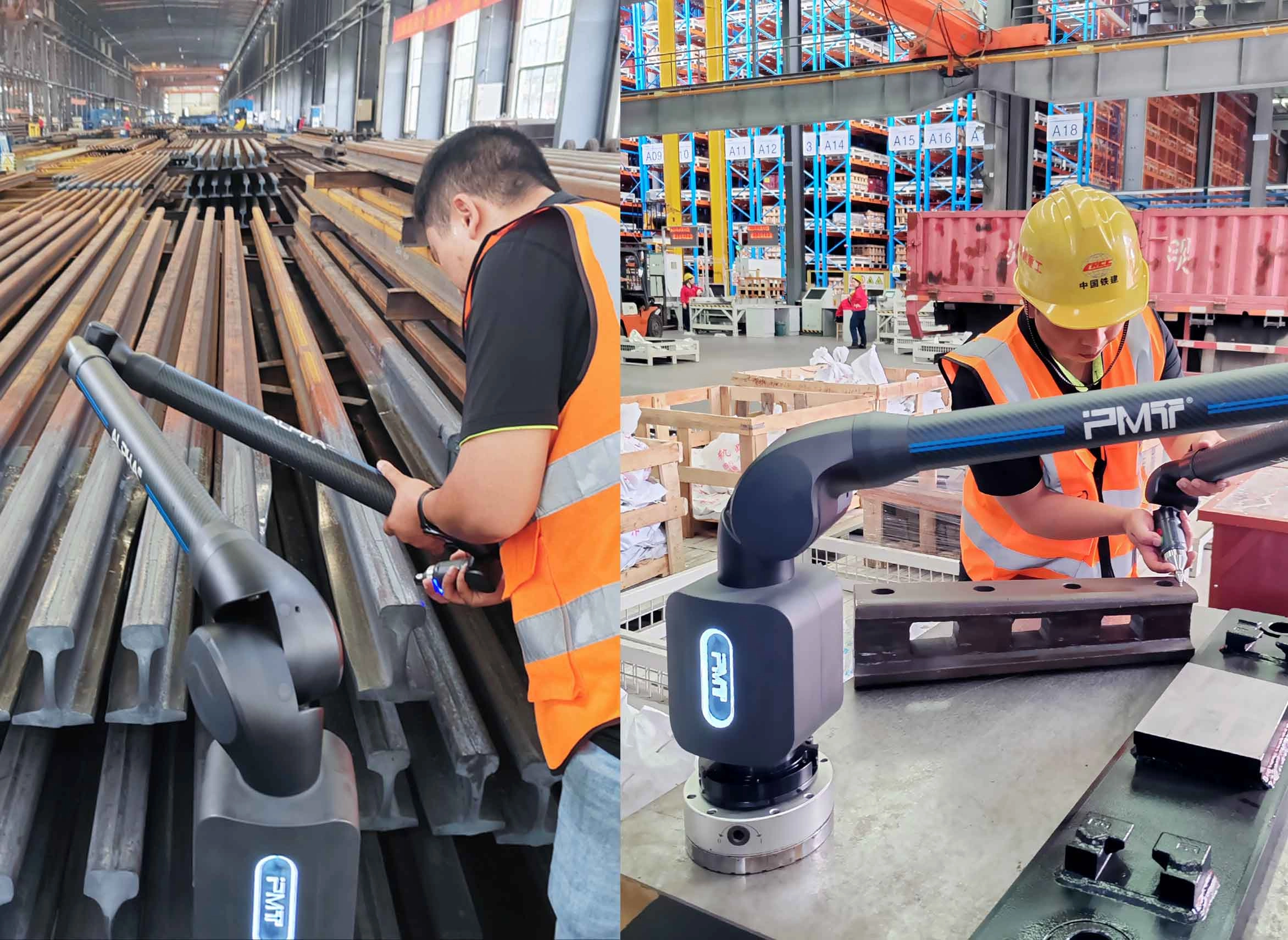

1.? Measurement of Rail Track

In large-scale projects, improving rail tracks or laying temporary tracks demands strict quality control. The PMT portable CMM offers precise geometric detection and maintenance, ensuring the stability and high quality of the rail track.

PMT measuring arm allows for rapid measurements of sample batches using the software’s “multipiece inspection” feature. This straightforward process allows for direct program saving and easy report archiving.

2.? Measurement of Valve Body

Valves are crucial for fluid control in hydraulic projects, regulating flow, controlling pressure, and preventing backflow.

The valve body constructs the flow path and withstands water pressure, requiring precise measurements for optimal functionality. The cylinder head ensures accurate linear or rotary movement, while ball valves rely on the valve stem’s rotation to open or close, ensuring proper pump station operation.

Therefore, it is essential to use the PMT portable measuring arm during valve manufacturing and maintenance to assess valve body deformation and sealing surface roughness.

The PMT portable measuring arm offers a full measurement range, high stability, portability, and efficiency, making it ideal for all stages of hydraulic construction including component validation, production monitoring, certification, after-sales analysis, and assembly accuracy, effectively meeting diverse measurement needs and improving product quality.

Conclusion

The hydropower project serves as a global model of national governance, significantly benefiting society and driving the development of related industries. Likewise, PMT has always been dedicated to supporting inspection processes with its self-developed measuring arms across industries, offering more professional “PMT solutions” worldwide.