In modern medical device manufacturing, precision is essential for ensuring product safety and user trust. Every implant, surgical tool, diagnostic component, and plastic molded part must meet strict dimensional requirements to guarantee performance and compatibility. However, as product designs become more complex and regulations more demanding, manufacturers need measurement methods that are both accurate and highly flexible.

At this point, portable CMMs have become an important technology. Unlike traditional fixed CMMs that require stable temperature-controlled rooms, portable devices offer mobility, ease of use, and the ability to measure directly in production environments. This makes them especially suitable for medical manufacturers seeking consistent quality and faster production cycles.

What Are Portable CMMs? Key Features and Measurement Principles

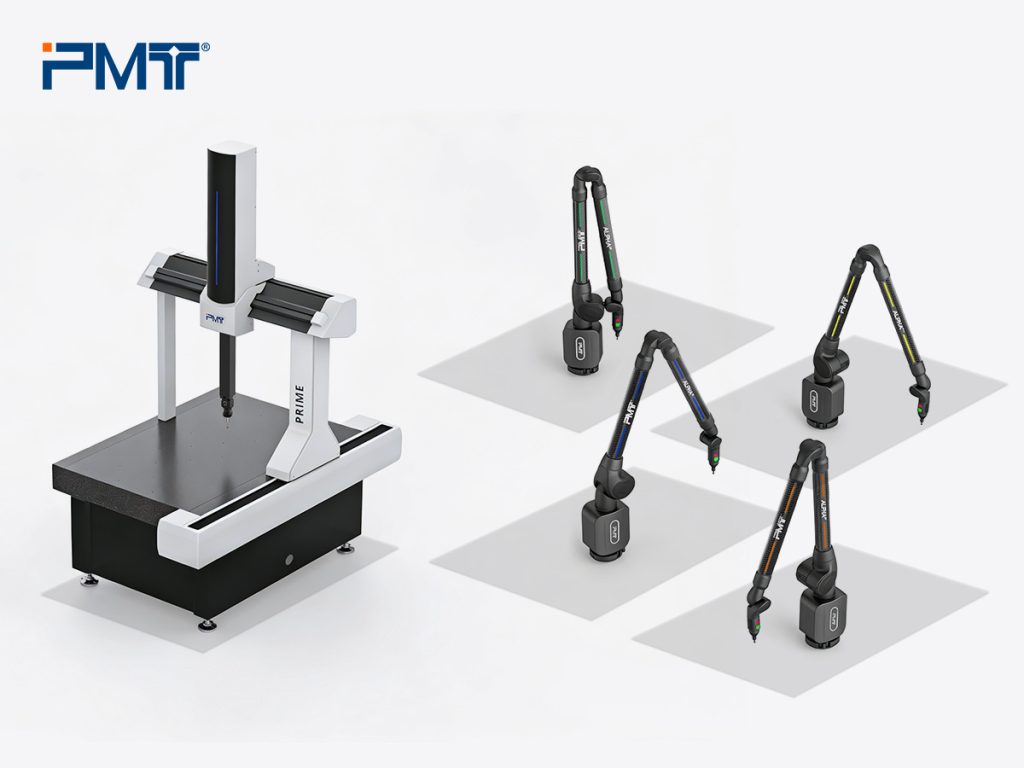

To better understand their value, it is useful to look at what portable CMMs are. A portable CMM is a mobile 3D measuring device, commonly available as a portable measuring arm or paired with a laser scanner. These tools allow operators to capture precise spatial data by touching the surface with a probe or scanning it with a non-contact sensor.

Because portable CMMs do not require a fixed installation or a special measuring room, they can be quickly deployed anywhere on the shop floor. This flexibility reduces downtime, supports multiple workstations, and improves responsiveness during mold validation, part inspection, or product development. In practical medical manufacturing environments, portable measuring arms such as PMT measuring arm?systems are often used to support flexible inspection tasks across different production stages.

Why Portable CMMs Fit Medical Manufacturing Requirements

As medical device manufacturing often involves small batch production, frequent design changes, and strict documentation requirements, portable CMMs align well with these needs. One major advantage is their ability to handle micro-scale components that require precise dimensional control. Whether it is a narrow cavity in a surgical guide or a curved surface on an orthopedic implant, portable CMMs can capture accurate 3D data.

Moreover, the portable CMMs?are?not affected by the environment?can be used inside cleanroom environments when appropriate procedures are followed. Their compact structure and easy-to-sanitize surfaces make them suitable for regulated production spaces. The devices also support flexible inspection routines, allowing manufacturers to switch quickly between different product types without resetting a large machine.

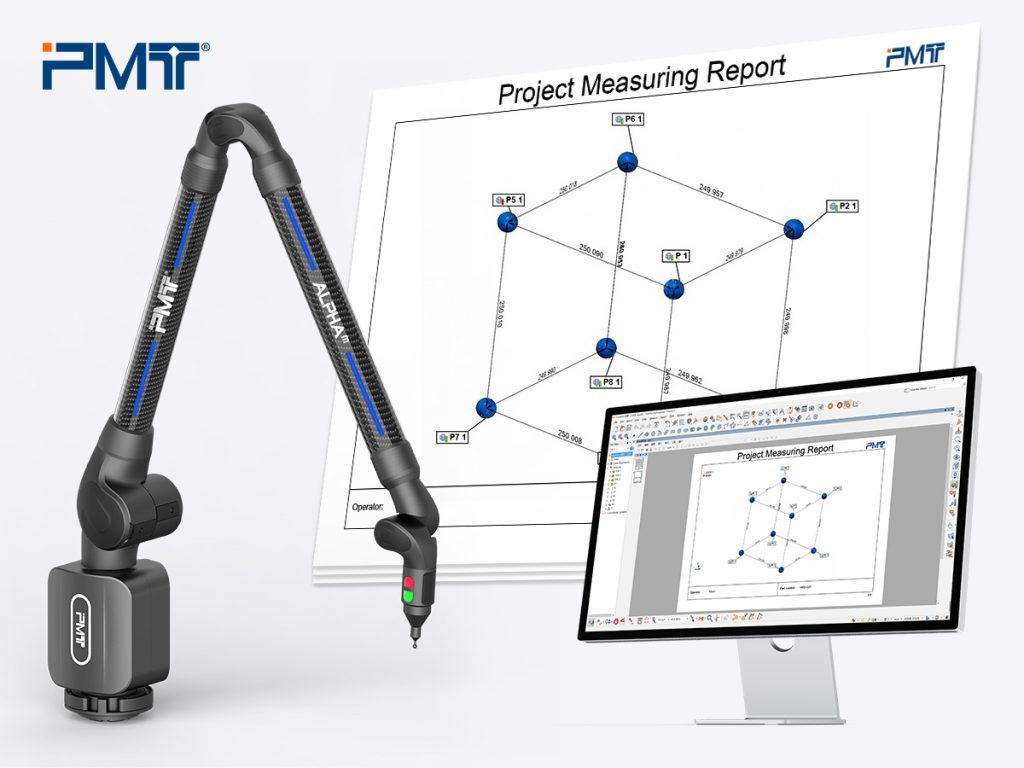

Another reason portable CMMs work well in this field is their strong data traceability. Modern systems store each measurement point, record operator actions, and generate standardized reports that support audits and compliance with international standards such as ISO 13485. For medical companies that must maintain detailed quality records, this documentation capability is critical.

Key Applications of Portable CMMs in Medical Device Production

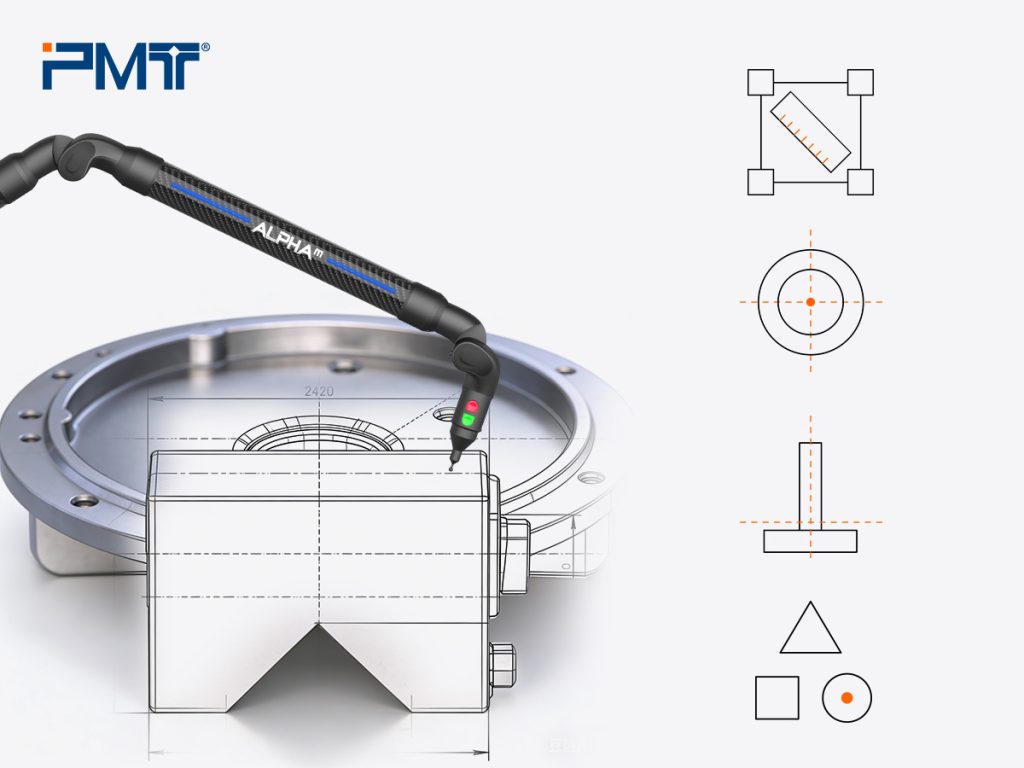

Because medical device manufacturing includes many different processes, portable CMMs play multiple roles throughout the production chain. For example, in precision mold manufacturing, they help verify core, cavity, inserts, and functional surfaces during machining and assembly. Rapid 3D data collection allows manufacturers to detect dimensional deviations early and reduce the risk of rework.

In practice, portable measuring arms like the PMT measuring arm allow engineers to access narrow cavities, deep holes, and complex freeform surfaces commonly found in medical molds and implant components. This capability is particularly valuable when traditional fixed CMMs or manual gauges cannot easily reach hidden features.

Portable CMMs are also widely used in orthopedic implant production. Since hip joints, knee components, and spinal implants have complex freeform surfaces, laser scanning can capture high-density point clouds for accurate comparison with CAD models.

For minimally invasive surgical tools or dental components, portable CMMs help inspect small geometries that require tight tolerances. Their non-contact measurement capability also avoids damage to delicate surfaces.

In addition, during product development and prototype testing, portable CMMs shorten the iteration cycle. Engineers can quickly verify design changes, perform fit-and-function analysis, and reduce delays between prototype versions.

Portable CMMs vs Traditional CMMs: A Practical Comparison

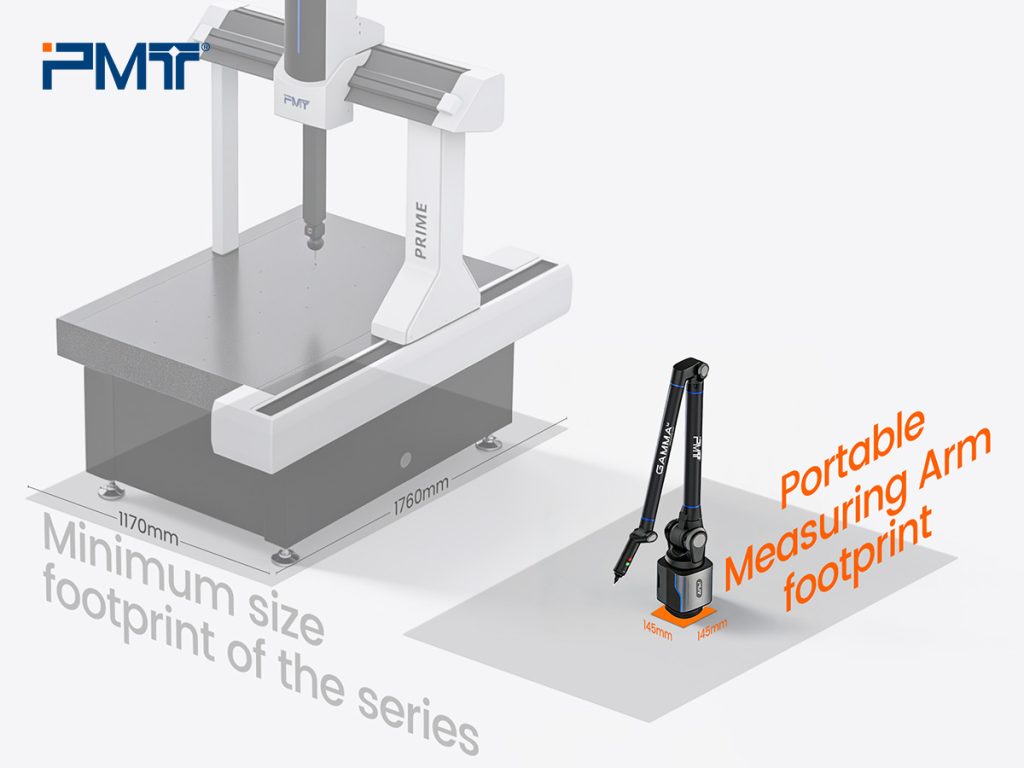

Although both types of CMMs provide precision measurement, their strengths differ. Portable CMMs offer mobility and ease of use, making them ideal for workshop inspection, mold validation, and real-time analysis. They allow operators to measure large parts or assembled products without moving them to a fixed room.

Traditional CMMs, on the other hand, deliver ultra-high accuracy under strictly controlled conditions. However, they require dedicated space, stable temperature, and trained operators, making them less convenient for flexible medical production environments.

When comparing cost, portable CMMs generally require lower investment in infrastructure. They do not rely on a fixed machine room and can serve multiple production lines. Their adaptable measurement range also supports wide product variation—an advantage in medical manufacturing where each project may differ in size or complexity.

Overall, portable CMMs provide a balance between precision, flexibility, and cost-effectiveness that matches the needs of modern medical plants.

How Portable CMMs Improve Quality Control and Workflow Efficiency

Beyond flexibility, portable CMMs significantly enhance quality control. Laser scanning systems can generate dense point clouds that allow engineers to compare surfaces with the original CAD model within seconds. This helps identify deviations in dimensions, roundness, flatness, or contour shape.

Additionally, portable CMMs support a complete digital workflow. From measurement collection to data analysis and reporting, every step can be automated or standardized. For example, PMT measuring arm systems combined with inspection software enable fast data acquisition, CAD comparison, and standardized report generation directly on the shop floor, reducing reliance on external metrology labs.

By supporting on-site verification and fast measurement cycles, portable CMMs also shorten production lead times. Operators can measure molds immediately after machining, check assembly accuracy on the line, or validate final parts before packaging—without sending them to a metrology lab. This improves response time and reduces overall manufacturing costs.

Choosing the Right Portable CMM for Medical Manufacturing

Because each medical manufacturer has different workflows and product types, selecting the right portable CMM requires considering several factors. First, the measurement range should match the size of the workpieces, whether they are small surgical tools or larger orthopedic molds. Second, accuracy and repeatability must meet industry requirements.

Manufacturers should also consider whether they need probe-based measurement, laser scanning, or a hybrid solution. Probe systems are suitable for high-accuracy single-point measurements, while scanning is ideal for complex surfaces and full-shape analysis.

Software capability is another key factor. A strong platform should support GD&T analysis, generate automatic reports, handle CAD data, and offer stable data management functions. Many manufacturers evaluate portable measuring arms, such as PMT measuring arm solutions, based on software compatibility, accuracy stability, and long-term technical support, especially in regulated medical environments.

Conclusion: Portable CMMs as a Catalyst for Quality and Compliance

In summary, portable CMMs have become an essential tool in medical device manufacturing. Their ability to deliver precise measurements, adapt to flexible workflows, and support regulatory requirements helps manufacturers improve efficiency and maintain consistent product quality. As the industry continues to evolve toward greater customization and faster development cycles, portable CMM technology will continue to play a central role in supporting accurate, reliable, and compliant production processes.

If you are looking for a trusted portable CMMs supplier, PMT provides high-quality measurement solutions designed for demanding medical applications. Contact PMT to learn how portable CMMs can enhance your inspection efficiency and product quality.