In modern industries such as energy, petrochemicals, and water treatment, large-diameter valves play a critical role in ensuring safe and reliable operation. However, due to their complex structures and large sizes, traditional inspection tools often struggle to deliver accurate results efficiently. To solve these challenges, the Portable Measuring Arm (also known as a portable coordinate measuring machine) has become a preferred solution. It combines flexibility, precision, and efficiency, making it ideal for large-diameter valve measurement.

The Challenge of Large-Diameter Valve Inspection

Large valves often feature wide openings, heavy structures, and intricate inner and outer surfaces. These characteristics make them difficult to inspect with conventional measurement tools such as calipers or fixed CMMs. The main issues include limited measuring range, difficulty in accessing hidden areas, and time-consuming setup processes. As a result, many industries face delays, higher costs, and risks of quality problems when relying solely on traditional methods.

Why Portable Measuring Arm is the Right Solution

Compared with other inspection tools, the portable measuring arm?stands out because it is lightweight, easy to move, and flexible to use directly on the shop floor. It allows operators to measure large workpieces without moving them to a fixed inspection room, saving both time and effort. For large-diameter valves, this mobility ensures that even the deepest internal structures and widest external surfaces can be accurately inspected.

Key Advantages in Valve Body Measurement

To understand its value better, let’s look at the specific benefits of using a portable measuring arm in valve body inspection:

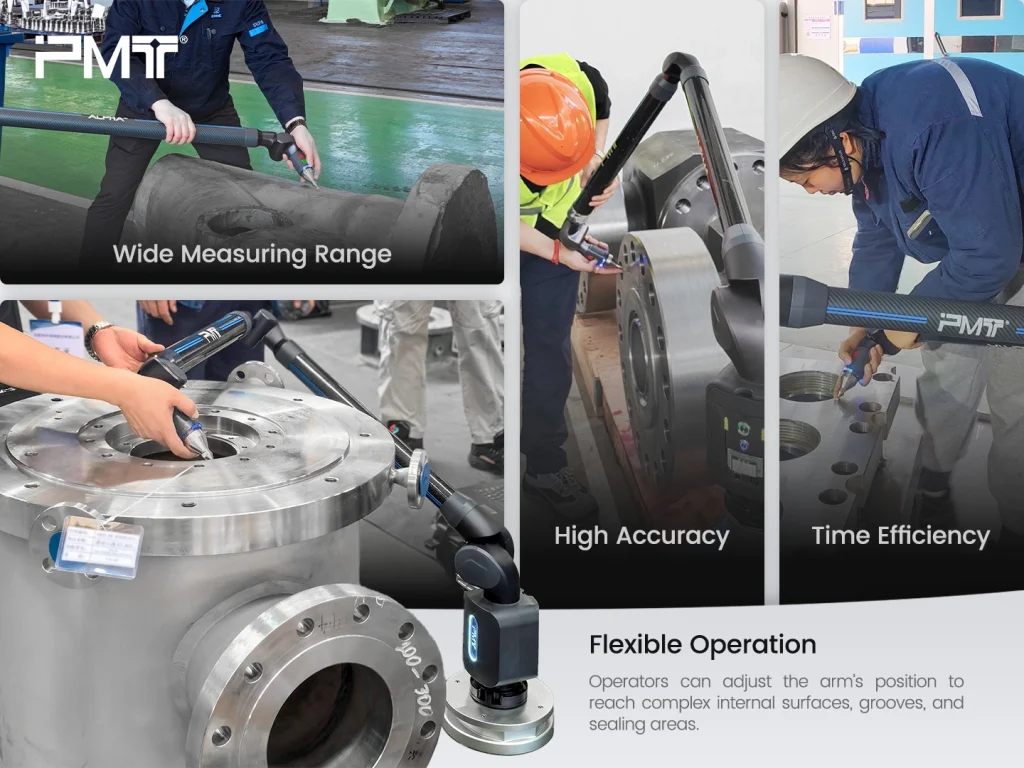

- Wide Measuring Range: The arm can easily cover large diameters that exceed the capability of standard gauges or handheld tools.

- High Accuracy: Despite its mobility, the system maintains strong precision, providing reliable data for quality control.

- Flexible Operation: Operators can adjust the arm’s position to reach complex internal surfaces, grooves, and sealing areas.

- Time Efficiency:?On-site inspection reduces downtime, as there is no need to transport heavy valves to a separate measuring facility.

These advantages directly help industries improve product quality and reduce inspection costs.

Practical Applications in the Valve Industry

In real-world applications, portable measuring arms are commonly used to measure valve body diameter, roundness, flange flatness, and alignment of internal passages. For example, when producing a high-pressure valve, every detail of the sealing surface must meet strict standards. With a portable measuring arm, technicians can quickly identify any deviation and make adjustments before final assembly. This ensures higher reliability and reduces the chance of leakage or operational failure in the field.

Improving Efficiency and Reducing Costs

Another key benefit of using portable measuring arms is the improvement in overall efficiency. Traditional methods require several tools and multiple steps, while portable arms allow all measurements to be performed in one setup. This not only saves time but also reduces human error. By cutting unnecessary processes and improving accuracy, manufacturers can significantly lower inspection and rework costs.

Future Outlook in Large-Scale Valve Inspection

Although many tools are used in industrial inspection, portable measuring arms are becoming increasingly important for large and heavy components. Their combination of precision, mobility, and efficiency makes them a valuable tool for valve manufacturers and end-users. As industries continue to demand higher quality and faster production cycles, the role of portable measuring arms in large-diameter valve inspection will only grow stronger.

Conclusion

Inspecting large-diameter valves has always been a difficult task due to their size and complexity. However, with the use of the Portable Measuring Arm, industries can achieve accurate, efficient, and reliable measurement results. From reducing inspection costs to improving product quality, this technology has proven to be an effective solution for one of the most challenging tasks in valve production. For manufacturers aiming to stay competitive, adopting portable measurement tools is no longer an option—it is a necessity.